AG Drive Mini

AG Drive Mini frequency inverters stand out for their compact design and excellent cost-effectiveness. They are suitable for various automation applications that use motors of up to 1 HP with frequencies up to 500 Hz. They feature an analog input from 0 to 10 V and Modbus RTU communication (via adapter).

User guideCompact and with two mounting methods, ensuring greater versatility

Available power ratings of 0.5 HP and 1.0 HP

Single-phase input (220 Vac) and three-phase output (220 Vac)

Multi-speed function: Select from various preset speeds

AG Drive Mini frequency inverters stand out for their compact design and excellent cost-effectiveness. They are suitable for various automation applications that use motors of up to 1 HP with frequencies up to 500 Hz. They feature an analog input from 0 to 10 V and Modbus RTU communication (via adapter). They also offer the option for DIN 35 rail mounting and have reduced dimensions, making the AG Drive Mini inverters the ideal solution for electrical panels and control cabinets.

Maximum motor power: 0.5 HP / 1.0 HP;

Rated output current: 2.6 A (0.5 HP) / 4.0 A (1.0 HP);

Maximum output current: 3.4 A (0.5 HP) / 5.2 A (1.0 HP);

Maximum input current: 5.1 A (0.5 HP) / 7.8 A (1.0 HP);

Power supply: Single-phase / Two-phase;

Rated voltage: 200 to 240 VAC RMS;

Input frequency: 50 to 60 Hz;

Output frequency: 0 to 500 Hz;

Switching frequency: 5 kHz, 10 kHz and 15 kHz;

Type of control: V/f;

Protection index: IP20;

Operation temperature: 0 to 50°C;

Relative humidity: 5 to 90%;

Analog input: 1 input (0 to 10 V);

Digital input: 3 digital inputs;

Communication: Modbus RTU*;

Output voltage at maximum frequency: 220 VAC (three-phase).

Documents

AG Drive Mini User Guide

Download

HMI made of silicone

The interface, constructed entirely of silicone, enhances the product’s durability and extends its lifespan. This robust design provides greater resistance to wear and environmental factors, ensuring reliable performance over time.

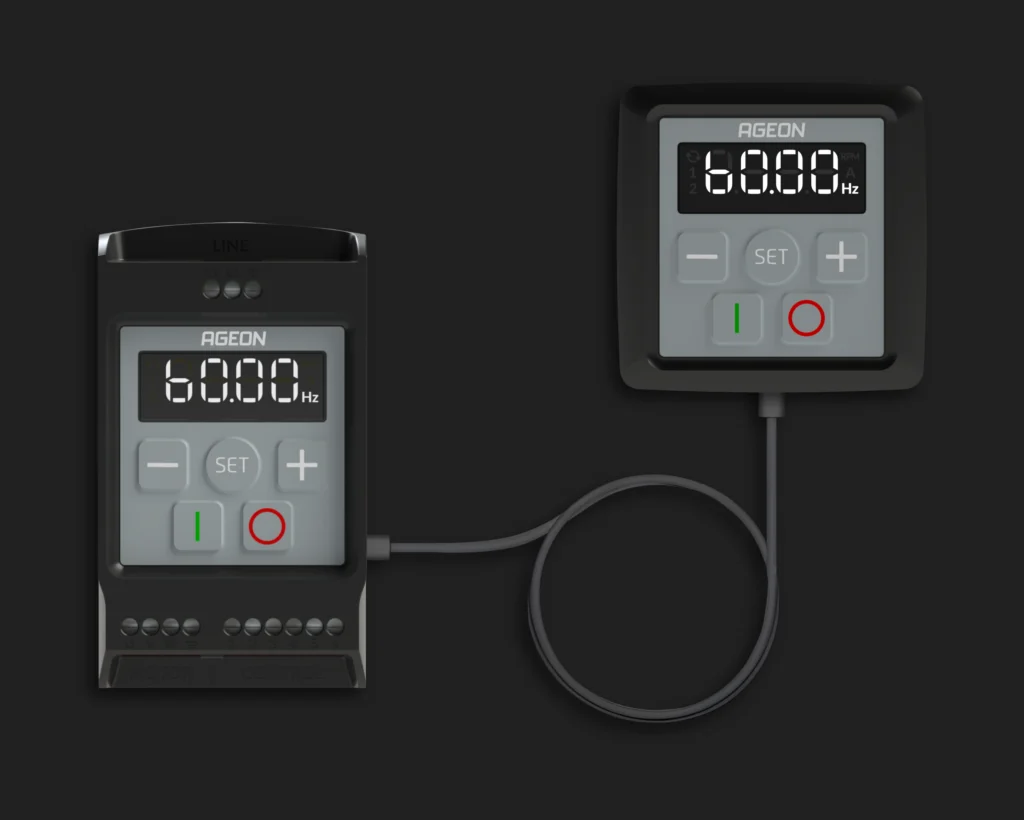

Remote HMI options

The AG Drive series offers the option for a remote HMI, enabling users to control and monitor the inverter from an electrical panel located at a distance or even in a different environment. This feature enhances flexibility and convenience, making it easier to manage operations in varied industrial settings.

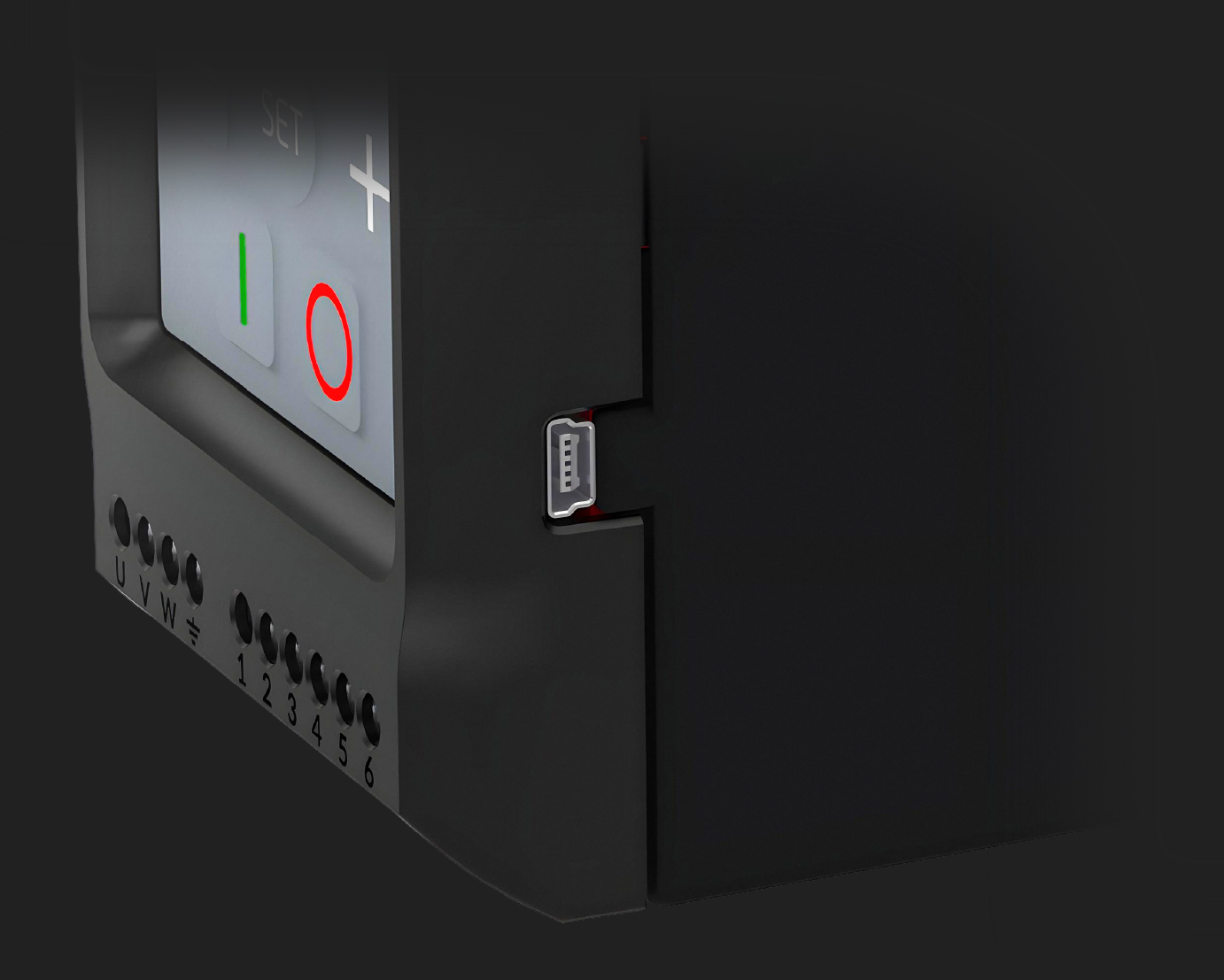

Modbus RTU / RS-485

The AG Drive Mini is equipped with Modbus RTU/RS-485 communication via a mini USB adapter, providing reliable and efficient data transmission, reception, and command execution. This feature allows integration with automation systems, enabling centralized monitoring and control of multiple devices. By utilizing this communication protocol, users can enhance system responsiveness, optimize workflow, and improve overall operational efficiency.

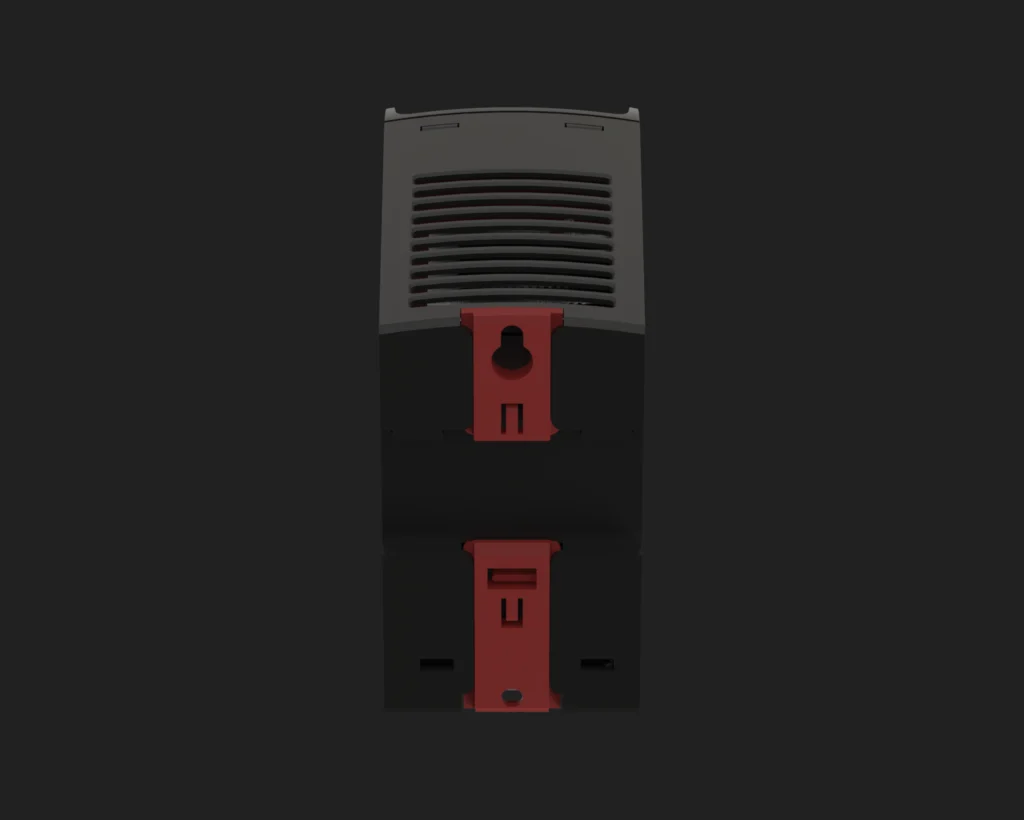

Multiple fixing methods

AG Drive Mini is designed to be integrated into electrical panels and control cabinets. Its compact design saves space, and its 35mm DIN rail set up simplifies the installation and use of the inverter. It can also be mounted using screws by adjusting the height of the rear mounting brackets.

Display with multiple measurement unit options

The AG Drive Mini inverters offer flexible display options that allow users to select the unit shown on the screen: RPM, Hz, or Amperes. This feature provides an adaptable way to monitor the performance of your frequency inverter with ease. Choose the measurement unit that best suits your application and gain clearer insights into your system’s operation. Experience enhanced convenience and control over your monitoring preferences.

Frequently asked questions

Inverters should be sized according to their rated current. While inverters and motors specify their rated powers for reference, the behavior of the loads must be considered when choosing an inverter. More demanding applications may require more robust equipment, such as those handling large inertias or maximum load particles. Using parameter P51 is essential for protecting the equipment’s integrity. For any questions regarding the product application, please contact our technical support at support@ageoncontrols.com

Frequency inverters perform the functions of motor protection and control, so it is not recommended to use contactors on the inverter’s output. Load operation can be controlled through the various methods described in the manual, and using contactors on the inverter’s output can even damage the product.

The AG Drive Mini inverters have an IP 20 protection rating and should be installed in enclosures with proper ventilation and spacing as indicated. It is important to consider the temperature and humidity of the installation location and, if necessary, install ventilation systems in the enclosures. Always take into account the presence of heat sources inside the inverter enclosure and ensure that components are kept at a distance to allow for efficient air circulation. The product manual (Chapter 3) provides best practices for installing the inverter.

To control the AG Drive Mini, commands can be sent via the product’s native HMI, analog signal, digital signal, multispeed function, remote HMI (two available options), and Modbus RTU communication.

The AG Drive Mini inverters support the use of both digital and analog potentiometers. To use potentiometers, connect them to inputs 1, 2, and 3 (as indicated in the manual) and adjust parameter P301. It is important to set the type of potentiometer in parameter P301: use value “0” for analog potentiometers and value “2” for digital potentiometers.